Ka sengoloa sa pele sa khalase ea fiber layer holim'a tlhahlobo ea lera, ke lumela hore motho e mong le e mong o lokela ho tseba hanyanefiber ea khalase, tšebeliso ea khalase e tsejoa ke bohle, e atisa ho sebelisoa bophelong ba rona ba letsatsi le leng le le leng, e sebelisoa haholo ho khabisa ntlo, thepa ea mohaho kapa thepa, kaha bohle rea tseba hore fiber ea khalase e na le tšebeliso efe? Ka mor'a moo, ke tla u tsebisa tšebeliso ea fiber ea khalase ho uena, ha re shebeng.

Fiberglass e ka sotheha ka thapo ea khalase, thapo ea khalase ke morena oa liropo, tšireletso e matla haholo, empa hape le ho hanyetsa kutu. Thapo ea khalase ha e jeoe ke metsi a leoatle, kahoo e sebelisoa e le thapo ea sekepe le thapo ea crane. Khalase faeba ka mor'a ho sebetsa, ka loha mefuta e fapaneng ya lesela khalase, lesela khalase ha e tšabe acid e, a sa tšabe alkali, kahoo e ka sebelisoa e le lik'hemik'hale fektheri filtara lesela. Lilemong tsa morao tjena, lifeme tse ngata li sebelisitse lesela la khalase sebakeng sa lesela la k'hothone, lesela la mokotla oa sethunya, mekotla ea ho paka. Mokotla oa mofuta ona ha se hlobo le ho bola, ha o na mongobo le ho senya, o tšoarella, o ratoa ke bohle. Fiberglass e sireletsa ka bobeli ebile ha e chese mocheso, kahoo ke insulator e ntle haholo. Lisebelisoa tsa ho kenya fiberglass li sebelisoa haholo lifekthering tse ngata tsa motlakase le lisebelisoa tsa motlakase naheng ea rona. Ka lebaka la tšebeliso ea lisebelisoa tsa khalase tsa fiber, ha li ntlafatse ts'ebetso ea motlakase feela, empa hape li fokotsa molumo oa motlakase, empa hape li fokotsa litšenyehelo tsa motlakase, ehlile ke linonyana tse tharo tse nang le lejoe le le leng.

Na tšebeliso e 'ngoe ea bohlokoa ea fiber ea khalase le polasetiki, ho etsa mefuta eohle ea lisebelisoa tse kopantsoeng tsa khalase, joalo ka lesela la khalase le kenngoeng ka polasetiki e chesang e qhibilihisitsoeng, ho etsa khatello ke "khalase", le ho feta polasetiki e matlafalitsoeng ea khalase e matla. , e ke ke ea e-ba mafome, 'me ho hanyetsa kutu, le kotara feela ea tšepe e nang le boima ba' mele, kahoo e sebelise ho etsa liketsoana, likoloi, khetla ea terene le likarolo tsa mochine ha li khone ho boloka lintho tse ngata feela. tšepe, empa hape ho fokotsa boima ba koloi, sekepe ka boeona, e le hore boima bo sebetsang bo ntlafatsoe haholo.

o tsepamisitse maikutlo kajeno, fiber ea khalase ea khalase e ka boela ea sebelisoa ho etsa lesela la thibelo ea mollo, ke thepa e ka sehloohong ea lesela la khalase, boea ba khalase, ke mofuta oa masela a roving tabby, SEBELISA lisebelisoa tse ntle tsa khalase, ka letoto. ea ho qhibiliha ha mocheso o phahameng, ho taka mohala, ho pota-pota, ho loha le lisebelisoa tse ling tsa theknoloji, matla a maholo a itšetlehile ka tataiso ea lesela la warp / weft. Lesela la unidirectional le ka lohuoa haeba ho hlokahala matla a warp kapa zonal. Thepa ea motheo ea lesela la fiber ea khalase ke alkali - khoele ea fiber ea khalase e sa lefelloeng, eo hangata e entsoeng ka mokhoa o ntlafetseng oa ho nosetsa. Lesela la fiber ea khalase ke ts'ebetso e ntle haholo ea lisebelisoa tse se nang tšepe tse sa sebetseng, tse nang le mokelikeli o motle, ho hanyetsa mocheso, ho hanyetsa kutu, matla a phahameng a mochine. Ponahalo ea sehlahisoa sa lesela la khalase e boreleli, e ntle, e lohiloeng e lekana, e bonolo, esita le holim'a bokaholimo bo sa lekanang le eona e ka ba le sekhomaretsi se setle. Lesela la fiber ea khalase le ka aroloa ka lesela le atolositsoeng la fiber ea khalase le lesela la fiber e sa atolositsoeng.

Lesela le atolositsoeng la fiber ea khalase le lohiloe ke khoele ea fiber e atolositsoeng ea khalase, e nang le ts'ebetso e ntle ea ho kenya letsoho le boima bo bobebe. Lintho tse fapaneng tsa ho kenya letsoho li ka finyelloa ka ho fetola sebopeho sa lesela le phekolo. Hangata e sebelisoa ka har'a likoahelo tse tlosoang, likobo tse timang mollo, likharetene tsa mollo, maqhama a ho atolosa le liphaephe tsa ho ntša mosi. E ka sebetsoa e koahetsoe ka lesela la aluminium foil le atolositsoeng ka khalase. Lesela le sa atolositsoeng la fiber ea khalase le lohiloe ka lesela le sa khaotseng la khalase, le na le litšobotsi tsa lesela le bonolo le le bonolo, le ka sebelisoa ka ho toba bakeng sa ho boloka mocheso oa indasteri le ho thibela mollo, le ka boela la sebelisoa e le lesela la motheo la lesela le koahetsoeng ka khalase.

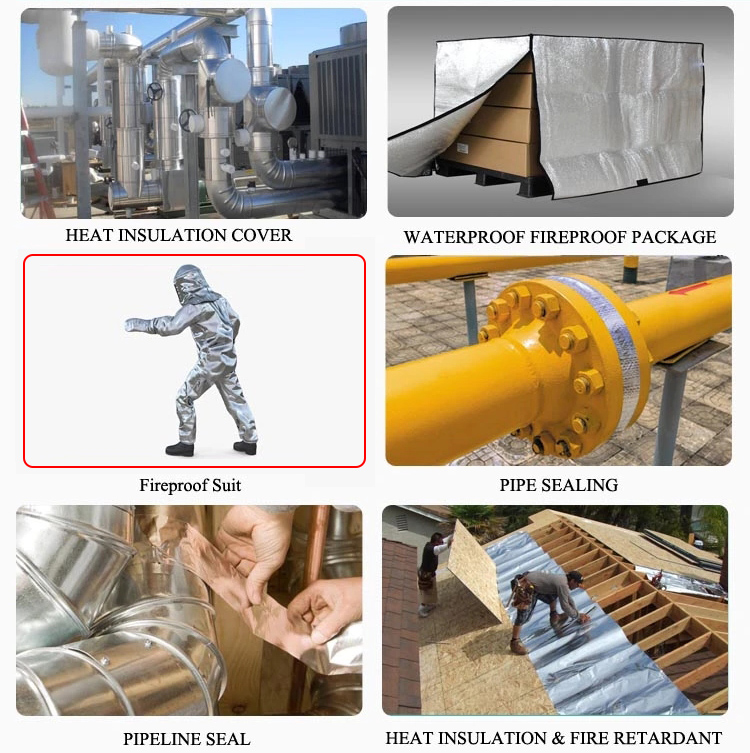

Mona ho bohlokoa ho hlahisa ts'ebeliso e tloaelehileng ea lesela la khalase, le lengata haholo, le se nang palo, joalo ka lebota le leketlileng la mosi, kharetene ea mollo, liaparo tsa mollo, kobo ea mollo, kobo ea ts'ireletso, lesira la mosi oa mollo, kobo ea mollo. Lithapo ha li che. Baki e ka tlosoang ea insulation le pad ea insulation. Kaho le tokiso ea foreimi ea likepe indastering ea likepe. Likhoebo tsa petrochemical ho sebopeho sa tšepe se kenyang mocheso, ho kenya letsoho le ho tjheseletsa li hloka ho beha. Sebaka sa sefofane, lik'hemik'hale, peterole, matla, metallurgy, lisebelisoa tse kholo tsa ho fehla motlakase, ho kenya motlakase, samente, mechine, kaho le likarolo tse ling. Li-laminate tsa koporo li entsoe e le lisebelisoa tsa motheo bakeng sa liboto tsa potoloho tse hatisitsoeng. E sebelisoa bakeng sa mocheso o phahameng oa ho tlosa lerōle la sepakapaka le ho hlaphoheloa ha lerōle la bohlokoa la indasteri joalo-joalo. Ka mohlala: samente, carbon black, tšepe le tšepe, metallurgy, lime kiln, ho fehla matla a mocheso le mashala le liindasteri tse ling. Khokahano e bonolo ea yuniti ea motlakase, boiler le chimney, ho kenya mocheso oa kamore ea enjene. E sebelisoa ka mosi, moea, moea, mosi, tsamaiso ea phepelo ea khase ea mats'eliso a lipeipi. Mefuta e fapaneng ea substrates e koahetsoeng. Boiler insulation. Ho roala lipeipi. Sistimi e 'ngoe ea ho koala mollo.

Empa molemong oa ho sebetsalesela la fiberglassE tlameha ho ela hloko lintho tse ling: haeba fiberglass monofilament e kenngoa 'meleng, ho bonolo ho baka pneumoconiosis, kahoo ha o sebetsa ho roala maske. Haeba u e kenya liphahlong tsa hao, e phaphatha ka makhetlo a ’maloa, ebe u e hlatsoa ’me u e omise, ’me haeba e ntse e le litšila, e phaphatha ka makhetlo a ’maloa. Haeba u e fumana letlalong la hao, hangata ho lokile, nka feela moriana oa allergy. Ho tsepamisitsoe maikutlo kajeno, fiber ea khalase ea khalase le eona e ka sebelisoa ho etsa lesela la thibelo ea mollo, ke thepa e ka sehloohong ea lesela la khalase, boea ba khalase, ke mofuta oa masela a roving, SEBELISA lisebelisoa tse tala tsa khalase, ka letoto. ea ho qhibiliha ha mocheso o phahameng, ho taka mohala, ho pota-pota, ho loha le lisebelisoa tse ling tsa theknoloji, matla a maholo a itšetlehile ka tataiso ea lesela la warp / weft. Lesela la unidirectional le ka lohuoa haeba ho hlokahala matla a warp kapa zonal. Thepa ea motheo ea lesela la fiber ea khalase ke alkali - khoele ea fiber ea khalase e sa lefelloeng, eo hangata e entsoeng ka mokhoa o ntlafetseng oa ho nosetsa. Lesela la fiber ea khalase ke ts'ebetso e ntle haholo ea lisebelisoa tse se nang tšepe tse sa sebetseng, tse nang le mokelikeli o motle, ho hanyetsa mocheso, ho hanyetsa kutu, matla a phahameng a mochine. Ponahalo ea sehlahisoa sa lesela la khalase e boreleli, e ntle, e lohiloeng e lekana, e bonolo, esita le holim'a bokaholimo bo sa lekanang le eona e ka ba le sekhomaretsi se setle. Lesela la fiber ea khalase le ka aroloa ka lesela le atolositsoeng la fiber ea khalase le lesela la fiber e sa atolositsoeng.

Lesela le atolositsoeng la fiber ea khalase le lohiloe ke khoele ea fiber e atolositsoeng ea khalase, e nang le ts'ebetso e ntle ea ho kenya letsoho le boima bo bobebe. Lintho tse fapaneng tsa ho kenya letsoho li ka finyelloa ka ho fetola sebopeho sa lesela le phekolo. Hangata e sebelisoa ka har'a likoahelo tse tlosoang, likobo tse timang mollo, likharetene tsa mollo, maqhama a ho atolosa le liphaephe tsa ho ntša mosi. E ka sebetsoa e koahetsoe ka lesela la aluminium foil le atolositsoeng ka khalase. Lesela le sa atolositsoeng la fiber ea khalase le lohiloe ka lesela le sa khaotseng la khalase, le na le litšobotsi tsa lesela le bonolo le le bonolo, le ka sebelisoa ka ho toba bakeng sa ho boloka mocheso oa indasteri le ho thibela mollo, le ka boela la sebelisoa e le lesela la motheo la lesela le koahetsoeng ka khalase.

Mona ho bohlokoa ho hlahisa ts'ebeliso e tloaelehileng ea lesela la khalase, le lengata haholo, le se nang palo, joalo ka lebota le leketlileng la mosi, kharetene ea mollo, liaparo tsa mollo, kobo ea mollo, kobo ea ts'ireletso, lesira la mosi oa mollo, kobo ea mollo. Lithapo ha li che. Baki e ka tlosoang ea insulation le pad ea insulation. Kaho le tokiso ea foreimi ea likepe indastering ea likepe. Likhoebo tsa petrochemical ho sebopeho sa tšepe se kenyang mocheso, ho kenya letsoho le ho tjheseletsa li hloka ho beha. Sebaka sa sefofane, lik'hemik'hale, peterole, matla, metallurgy, lisebelisoa tse kholo tsa ho fehla motlakase, ho kenya motlakase, samente, mechine, kaho le likarolo tse ling. Li-laminate tsa koporo li entsoe e le lisebelisoa tsa motheo bakeng sa liboto tsa potoloho tse hatisitsoeng. E sebelisoa bakeng sa mocheso o phahameng oa ho tlosa lerōle la sepakapaka le ho hlaphoheloa ha lerōle la bohlokoa la indasteri joalo-joalo. Ka mohlala: samente, carbon black, tšepe le tšepe, metallurgy, lime kiln, ho fehla matla a mocheso le mashala le liindasteri tse ling. Khokahano e bonolo ea yuniti ea motlakase, boiler le chimney, ho kenya mocheso oa kamore ea enjene. E sebelisoa ka mosi, moea, moea, mosi, tsamaiso ea phepelo ea khase ea mats'eliso a lipeipi. Mefuta e fapaneng ea substrates e koahetsoeng. Boiler insulation. Ho roala lipeipi. Sistimi e 'ngoe ea ho koala mollo.

Empa ts'ebetsong ea ho sebelisa lesela la fiberglass le tlameha ho ela hloko lintho tse ling: haeba monofilament ea fiberglass e kenngoa 'meleng, ho bonolo ho baka pneumoconiosis, kahoo ha o sebetsa ho roala maske. Haeba u e kenya liphahlong tsa hao, e phaphatha ka makhetlo a ’maloa, ebe u e hlatsoa ’me u e omise, ’me haeba e ntse e le litšila, e phaphatha ka makhetlo a ’maloa. Haeba u e fumana letlalong la hao, hangata ho lokile, nka feela moriana oa allergy.

https://www.heatresistcloth.com/

Nako ea poso: Sep-20-2022